How a product is made

Products are carefully made by women in our Community Factory in Kchass village, Siem Reap, Cambodia.

There are 6 sessions to show here is finish one product.

Community Factory

The place where SALASUSU products are made and a school is located in the rural village of Kchass, about 45 minutes by car from Siem Reap.

1 Selection

The producers must ensure all rush grass is sorted by size (thick and thin), length, and skin (dark spots or white) based on specific criteria. This process is crucial to maintaining the high quality of mat products

2 Dyeing

Coloring: The grass, bundled into a broom shape, undergoes dyeing in the traditional stove located behind the workshop. This intricate process requires careful monitoring as the dye permeates the grass, altering its color.

This section is particularly challenging to maintain consistent quality due to numerous factors involved, including sunlight exposure, natural variations in rush color, water levels, and heat.

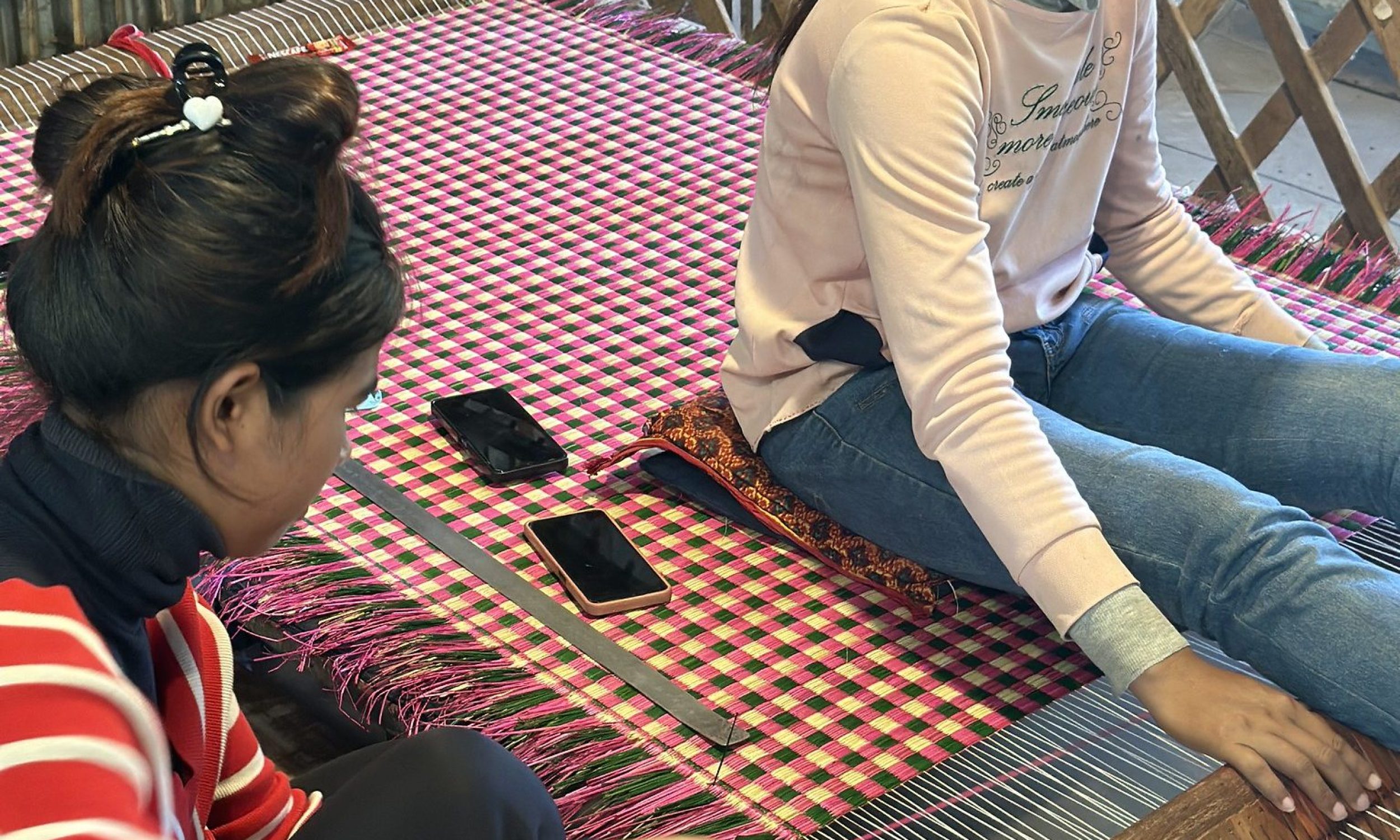

3 Weaving

Craftspeople working with traditional weaving machines often need to collaborate closely, utilizing their skills and techniques to produce a variety of mats and patterns. This teamwork allows them to efficiently manage the intricate processes involved in weaving, from selecting materials to creating complex designs. Each artisan may specialize in different aspects of the craft, such as setting up the loom, threading, or weaving specific patterns, ensuring a high-quality and diverse range of products. The traditional methods combined with skilled craftsmanship result in unique and culturally significant items that reflect the artisans’ expertise and creativity.

4 Cutting

Cutting involves precisely cutting out all the necessary parts for the product. Efficiency and careful work are required to ensure that each piece is accurate and fits together properly during assembly. This step is crucial as it impacts the overall quality and durability of the final product. Using sharp tools and proper techniques, craftspeople meticulously cut materials, paying attention to measurements and details to avoid waste and ensure consistency in production.

5 Sewing

Sewing is a critical step where the mats are carefully stitched together. Special attention is required when sewing hard grass mats and fabric combinations. This process demands patience and precision to ensure the seams are strong and the final product is well-constructed. The quality of sewing significantly influences the durability and aesthetic appeal of the mats.

Hand sewing allows for intricate details and personalized craftsmanship, which can enhance the uniqueness and quality of the product. This method is especially important for complex patterns and delicate designs that machines cannot replicate accurately. These techniques are essential, depending on the design complexity and the desired outcome, showcasing the versatility and skill of the craftspeople.

6 Quality Check

Quality checking is a crucial step in the production process, ensuring that each product meets the required standards and specifications. During this phase, every aspect of the mat is inspected, including material quality, cutting precision, sewing integrity, pattern consistency, and overall finish. This thorough inspection helps maintain high standards, ensuring that each product is durable, functional, and aesthetically pleasing. Quality checking also helps identify and address any issues early, preventing defective products from reaching customers.

Meet our Craftspersons

The poorest families living around the community Factory received various education and support while working there, such as learning how to read and write Cambodian, using a sewing machine, and managing household finances. In the process of learning, they gain both skills and confidence and eventually set off towards their own futures. Some products have the name stamp of the person in charge.